Calculating a board foot of lumber can be confusing but is actually quite straightforward. One board foot is 12 inches wide, 12 inches long, and 1 inch thick. This unit of measurement is used by the hardwood industry to calculate the volume of a board instead of its length. As lumber is often sold in random widths ranging from 2” to 16”, units of measurements like linear feet can’t be used to price materials.

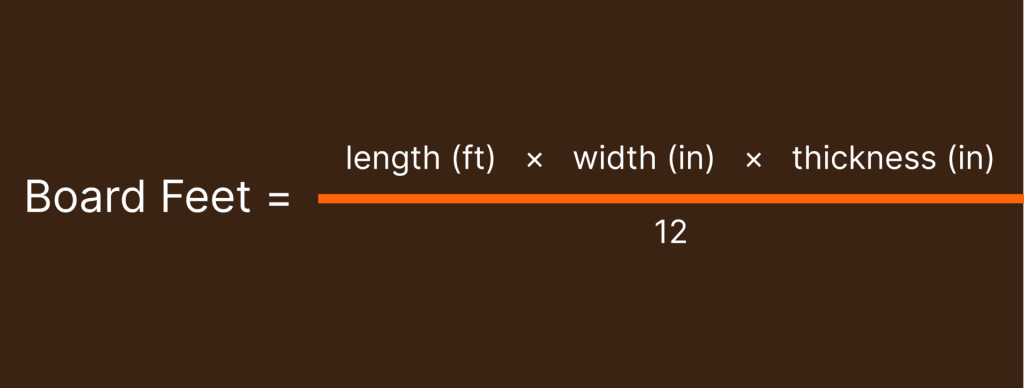

Woodworkers and manufacturers will often calculate more than the amount of board feet they need for a project. As accidents can occur and project scope changes, it’s always better to have additional materials on-hand. More often than not, trying to find more boards that match or mesh well with the original colors and wood grain will be difficult. While there is a calculator to help determine the amount of board feet needed for a project, the formula isn’t difficult to understand. The board foot formula is:

Just make sure to pay close attention to the units of measurements:

- Length is measured in feet

- Width and Thickness in inches.

What is Linear Feet in Lumber?

Compared to board feet which calculates the volume of a board, linear feet is simply the length of a board. This measuring (and pricing) method is commonly found at big box stores in construction grade lumber. Lumber sold by linear feet is typically separated into different categories and prices based on the different lengths and widths. However, these boards are generally only used in projects that don’t need specific widths or thickness.

How is Lumber Sold?

As suppliers, lumber yards, and sawmills measure their products by board feet, they also use this measurement to calculate the price of their lumber. There are occasions when lumber is sold in linear feet but lumber is most commonly sold in board feet. This allows woodworkers and manufacturers to buy lumber in various widths, lengths, and thickness for their needs.

Is Rough Cut Lumber Cheaper Than S4S?

At first glance, it would seem that rough lumber would be cheaper than dressed lumber ( S2S, S3S, S4S). Especially since there isn’t any labor involved in milling the surface. However, there are a lot of factors to consider when calculating the cost of lumber. Indeed there are labor costs mills charge for each stage of surfacing. Furthermore, the price also includes the material that is removed. For example, a board that is 1 inch thick will be milled down to ¾” thickness during the planing process. Despite the additional costs, dressed lumber costs can even out or be more cost-effective when compared to rough lumber’s shipping, time, labor, and machine tool costs. Read more about the advantages of dressed lumber!

Heritage Oak LLC Select Dressed Lumber

Our S2S lumber, S3S lumber, and S4S lumber from Heritage Oak is perfect for busy manufacturers and woodworkers of all skill levels. Make your next project easier with S4S lumber from quality ozark hardwoods. Do you have additional questions concerning S2S lumber, S3S lumber, or S4S lumber? Reach out to our professional hardwood experts at Heritage Oak today!